Hydraulic latching tool quickly connects pressure control string to the wellhead

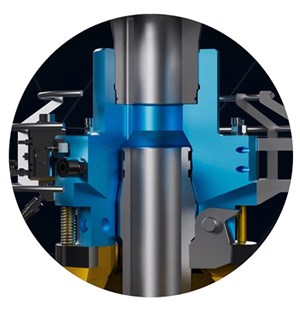

Hunting’s commitment to developing technologies to improve safety and productivity in pressure control operations led to the development and launch of its Ezi-Latch product, Fig. 1. Designed to streamline the connection of the pressure control tool string to the wellhead, using hydraulics, Ezi-Latch eliminates the need for human intervention during the connection process, thereby minimizing the risk of injury. This innovative solution enhances rigging efficiency, making rig-up and rig-down processes quicker, safer and more streamlined.

While Hunting was not the first to market hydraulic wellhead connectors, our deliberate approach allowed us to gain valuable insights from customers and further enhance an already viable solution. By collaborating closely with key stakeholders, Hunting was able to fine-tune Ezi-Latch to address specific pain points and industry challenges. The advantages of the latch lie in its potential to improve safety and productivity in pressure control operations. By automating the connection of pressure control equipment (PCE) to the wellhead during fracturing procedures, the technology effectively minimizes the risk of injury and expedites the process, resulting in increased operational efficiency and cost-savings, Fig. 2.

Well intervention product line. The Ezi-range, and its design philosophy, is one mirrored with other Ezi-branded equipment with the Hunting Well Intervention product line and is synonymous with innovation that enhances operational efficiency and safety. Its inaugural product, the Ezi-Load stuffing box marked a significant turning point in stuffing box technology and pressure control equipment, Fig. 3. Unlike its predecessors, the new-style stuffing box introduced a novel feature: top-loading capability. This innovation eliminated the need for cumbersome disassembly during rigging up and down, streamlining operations and reducing NPT.

Building on this momentum, Hunting expanded to include the Ezi-Catch in 2005, a complementary addition to the Hunting Tool Catcher. The true innovation, however, came in the form of the Ezi-combo—an integration of the Ezi-Load stuffing box and Ezi-Catch—creating a seamless and comprehensive solution for pressure control operations. This integration not only highlighted the product line’s commitment to innovation but also showcased its dedication to delivering tangible value to the market.

Hunting Well Intervention, a division of Hunting Energy Services, continued to uphold the Ezi criteria—robustness, efficiency and ease of operation—in their ongoing product development. Notably, they elevated wireline valve technology by introducing Ezi-Close cylinders. These cylinders introduced a pressure-balanced system that enabled manual closure against well pressure, with the added capability to rapidly close under accumulated pressure, vastly reducing closure time. A game-changing addition, this innovation exemplified Hunting's focus on practical solutions that address industry challenges head-on.

In 2016, Hunting introduced the Ezi-Shear seal valve, which offers a compact and reliable "shear and seal" mechanism for slickline and wireline tubing. Beyond its operational benefits, the Ezi-Shear seal valve addressed critical aspects of operational safety, reliability and well integrity. The industry had a new standard for emergency wellbore isolation, further solidifying Hunting's reputation as an industry leader in innovative technology.

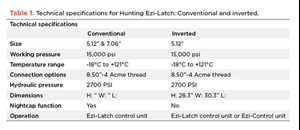

Inverted Ezi-Latch. The inverted latch system uses the same hydraulics and latching mechanism as the original Ezi-Latch, with the removal of the night cap arm, Fig. 4. Connecting the system to the PCE string instead of the wellhead means less equipment is required to operate a multi pad well, Table 1. The simplicity of the design, developed from our existing Ezi-Catch tool catcher, makes rigging up and down quicker, safer and easier for operators. The failsafe design features three hydraulic cylinders that are remotely actuated to set a lock ring securing the Ezi-Latch connection and lock it in position. Once locked in place, it provides a pressure-tight barrier to begin operations, controlled via a stand-alone hydraulic control panel. The unique profile of the lock ring and the use of springs ensures the lock ring stays in position in the event of hydraulic failure.

Field trials, success and expansion. The journey of the Ezi-Latch from conceptualization to commercialization was marked by meticulous development and rigorous testing. The engineering teams at Hunting’s facilities in Houston and the UK worked to refine the design, ensuring it met and exceeded industry requirements. To validate its performance and gather real-world feedback, Hunting partnered with two major service companies, conducting comprehensive trials that solidified the Ezi-Latch's efficacy. With its successful commercial launch in early 2022, Ezi-Latch quickly gained traction across oil and gas basins in the U.S. and Canada. Feedback from these regions has been overwhelmingly positive, underscoring the product's transformative impact on pressure control operations.

Furthermore, Hunting expanded the Ezi lineup with complementary offerings, including customized transport frames and the innovative Ezi-Control unit, which represents a significant advancement in hydraulic and grease injection technology. It seamlessly integrates with the Ezi-Latch system and provides comprehensive control over the pressure control tool string, encompassing the greaseless cable pack-off (pressure control head), wireline valve, tool trap and full Ezi-Latch functionality. This all-in-one solution epitomizes Hunting commitment to operational excellence.

What our clients say. Feedback from major service companies in the U.S. and Canada has been positive, given the partnership during the process. One operator noted that the “simplicity and robustness of the system were some of the attributes that initially piqued our interest.” Operational efficiencies at the heart of the design also mean significant savings on “the cost, both the initial investment and cost to operate.” Ezi-Latches have been in the field for two years, and clients have been impressed with all aspects of the system. Another key advantage of Hunting’s Ezi-Latch, according to a pressure control equipment operations support manager “is the low maintenance, ease of operation, and overall operational effectiveness have kept us at the forefront of the industry.”

Global footprint. Hunting’s commitment to providing high-quality equipment and superior support extends beyond innovation—it encompasses a global manufacturing footprint strategically positioned near major oil and gas production regions. With flagship manufacturing facilities in Houston, supported by facilities in Houma, La., and Badentory UK, as well as Singapore, Dubai, Saudi Arabia and Norway, Hunting ensures that its solutions are readily available to operators worldwide. As Ezi-Latch continues to gain traction in North America, the potential for further expansion into other regions and offshore applications becomes evident. With offices strategically located in the UK, Norway, MENA and Singapore, Hunting is well-positioned to support inquiries and serve the evolving needs of the global oil and gas industry.

Emphasis on knowledge management. Beyond the hardware, Hunting places a strong emphasis on knowledge transfer and user training. The seamless transition to operating this equipment is facilitated through comprehensive training and product familiarization. By building a dedicated technical support team, Hunting Group ensures that its clients have the resources and assistance they require to optimize their operations effectively.

CONCLUSION

Ezi-Latch is an example of how commitment to innovation, safety and operational efficiency can redefine industry standards. Its journey from inception to commercialization is a testament to Hunting’s ability to listen, collaborate and deliver solutions that address difficult challenges faced by the oil and gas sector.

Lead image: Hunting manufactures equipment and provides services for downhole intervention to optimize operations in producing wells.

- Regional report: Brazil sees abundant problems and opportunities in 2025 (March 2025)

- Uncertainty remains the greatest obstacle to better Canadian upstream performance (February 2025)

- Wood’s Hall sees oil and gas projects progressing while energy transition work gains scale (February 2025)

- What's new in production: Ionic liquids (December 2024)

- OEE insurance as a well control tool (December 2024)

- Sustainability: The relationship between upstream operations and blue hydrogen production (November 2024)